What challenges do 3D CAD models solve?

The arrival of CAD (Computer Aided Design) was a revolution for many industries as computers were introduced to create and modify a design. What began as 2D drawings consisting of drawings, isometric designs, and machine parts plans quickly culminated in 3D representation.

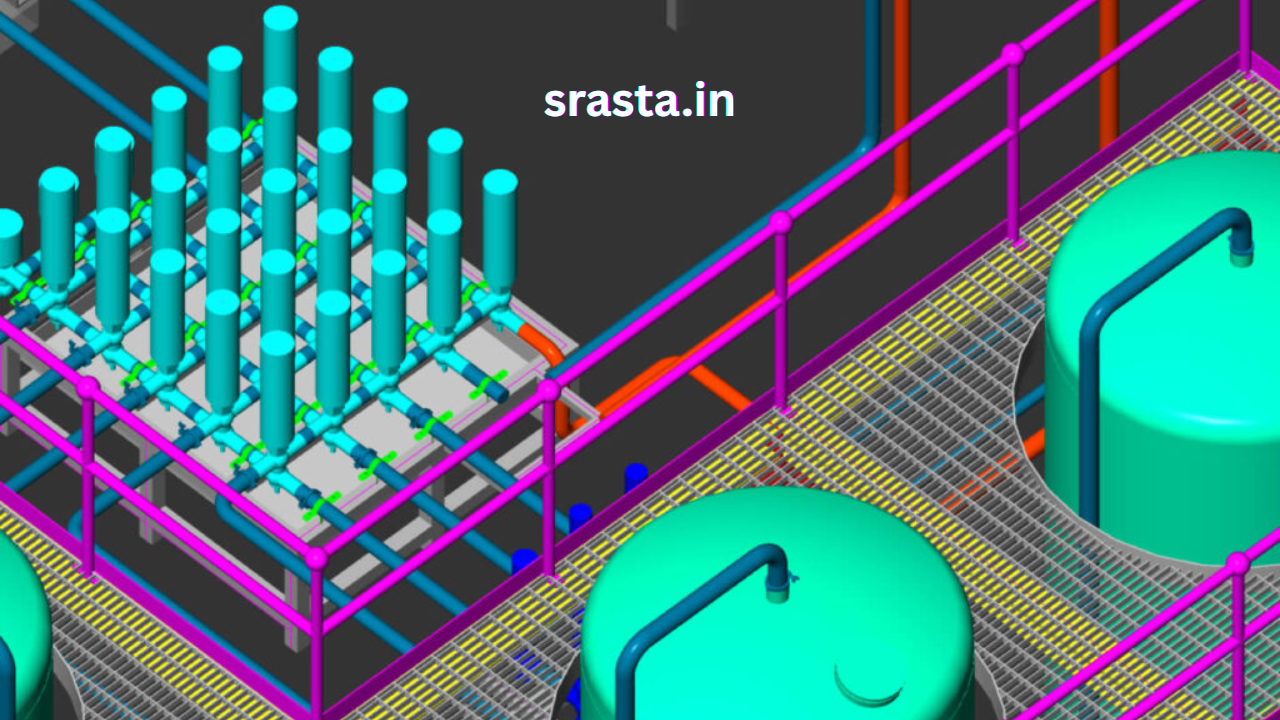

3D CAD removed the necessity of drawing lines on paper and introduced an automated process that designers, engineers, and numerous professionals used to accurately represent and visualize a subject utilizing a collection of points in three dimensions.

With progressive technological advancement, 3D CAD software can now offer much more than simple three-dimensional visualization. It has enabled a plan to come alive on screen through brilliant design techniques and precision. In addition, 3D CAD has transformed how design teams work and how they can create a prototype in just a fraction of the time, previously unimagined. To illustrate the profound impact of 3D CAD modeling on the design process, consider creating an informative infographic summarizing its benefits and advancements in the field of computer-aided design.

How has 3D CAD Improved the Design Process

With 3D CAD modeling, design engineers can reproduce a prototype that can be experienced closely thanks to the state-of-the-art software available in the market. Following are some of the challenges that 3D CAD modeling is solving in the design process:

-

Cost Reduction

Traditional 2D modeling could not offer the feel and 360-degree design of the product, causing continuous changes in structure, resulting in enormous costs for changing and creating a better design. Imagine doing the same for numerous products and the prices it would impose on the manufacturing companies.

Today’s 3D modeling has genuinely changed how we look at prototypes and how we can restructure them at the drop of a hat. Designers can now create, modify, and inspect a product hundreds of times before building it actually.

This, in turn, has led to enormous time and cost savings as engineers now do not have to go back and forth for restructuring a prototype. It can all be done easily using specialized CAD drafting software on your computer screen.

-

Faster Error Recognition

3D CAD modeling offers designers the power to quickly recognize any flaws or clashes in the model as now they can apply various layers and tests to visualize and simulate the design to find the right fit. With 3D computer-aided design, the chances of human error are also mitigated significantly as the software quickly alerts the user of the mistake.

It makes way for better communication and collaboration too. It eliminates silos and offers more accessible communication among all the stakeholders. Multiple teams can work together on the model to understand how different elements in the design are interacting with each other. This leads to better clash detection and error resolution.

This was one of the biggest challenges earlier as with 2D models, engineers and architects were never able to identify and understand how different components in the building interacted with each other. This led to errors and clashes during the building construction/ product development stage which led to significant wastage of time, money, and resources.

-

Improved Quality

It has already been discussed that designing with 3D CAD enables a designer to incorporate numerous changes to each segment, which is nothing but clicking, dragging, or selecting certain sections.

The enhanced visualization offered via 3D modeling enables a user to analyze and carefully examine the changes from each and every angle, making it easier to authenticate the changes and sharpen the design beautifying it further.

While traditional design took way too much time, making the task tedious, 3D modeling’s virtual investigation enables users to produce edited and iterated versions in less than 15 minutes. Alongside this, the user-friendly approach of the 3D software lessens the learning curve, keeping the team engaged, offering higher productivity, and reducing manual errors.

-

Detail Oriented

3D modeling enables designers to create any structure while maintaining production abilities and aiding in easily bringing together unimaginable visions.

Today’s 3D modeling offers an extent of incorporating depth in a design that 2D line diagrams could not provide. It also lets engineers review the plan in a way that they can understand the depth of the product without any limitations.

Leveraging this technology, teams can go in-depth into a design, make quick alterations, and present the prototype in a detailed manner while keeping everyone abreast of the latest developments.

Future of 3D CAD Modeling

The future of 3D modeling looks extremely bright. With increased personalization of designs, better iterations, collaboration and error resolution, 3D CAD modeling significantly enhances customer experience, leads to reduced reworks, and time and resource wastage. This makes the whole design and construction process more efficient and productive.

Today, there is also the incorporation of AI, VR, and Augmented reality in CAD, which is taking the platform to new heights.